Ever wonder what it takes to build a cartoner that shrugs off high-pressure hoses, caustic foams, and late-night “clean-everything” crews? At ADCO, we’ve been answering that question since the mid-1960s, and nearly a third of every machine we ship today is purpose-built for rigorous washdown duty. Sanitation standards keep rising—so do our design expectations. Here’s how decades of hands-on experience shape every ADCO washdown build.

Life in the Splash Zone

Cartoners rarely touch unpackaged products, so on paper their hygiene requirements look lighter than those for fillers or thermoformers. In practice, they sit right next to those machines and get drenched by the same chemical fog. Overnight crews often treat every asset alike, so our cartoners are engineered to withstand the full onslaught of overspray, detergent residue, and high-pressure rinse.

When Chemistry Beats Stainless Steel

Stainless isn’t invincible. One customer spotted rust on a brand-new machine with 304L stainless steel only weeks after installation. Lab tests traced the problem to chloride cleaners used elsewhere in the room; a fine mist settled on every surface and, without a thorough rinse, attacked the stainless steel. The machine was sound—the cleaning protocol wasn’t. The lesson is clear: corrosion control is equal parts material science and disciplined rinse-down procedures.

Carbon Contamination: An Invisible Threat

Stainless steel can corrode when carbon dust embeds on its surface, often the result of carbon-steel tools or grinding debris. All ADCO frames and guards are fabricated exclusively from stainless steel, and optional passivation or micro-polishing removes any residual carbon after welding. The result is a pristine finish that endures decades of sanitation cycles.

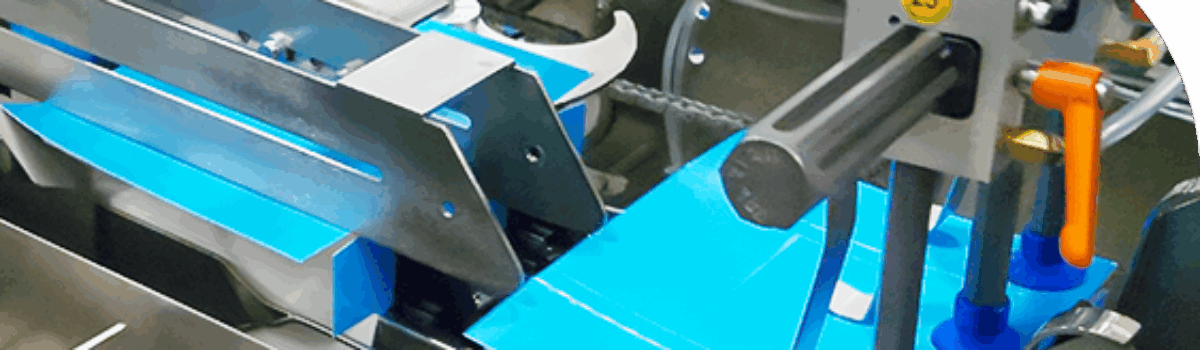

Clear Sightlines, Zero Fog

Polycarbonate guard windows cloud within weeks under harsh chemicals. Replacing them twice a year is costly, so we developed custom stainless-steel hex-mesh panels. They bolt straight into our guard openings, preserve operator visibility, and never haze or crack—delivering a permanent, sanitary solution.

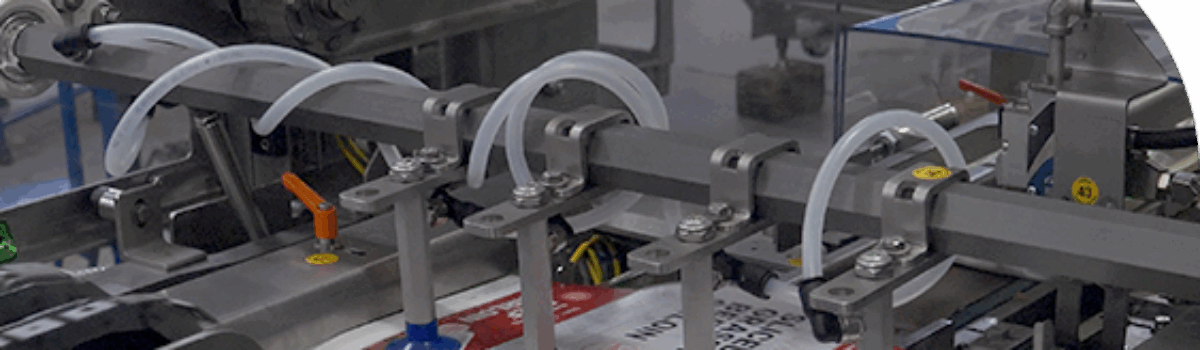

Chains: Protection Over Perfection

Standard stainless chain stretches; premium non-stretch S/S alternatives come with long lead times and steep prices. Our answer is a corrosion-resistant coated steel chain, paired with a post-wash application of food-grade dry-silicone spray. It takes discipline, but this method shields links without flooding the system with lubricant, an issue we often see with automatic oilers.

Know What to Cover And Document It

Our baseline washdown build includes IP65 sensors, solenoids, and enclosures, some processors upgrade to IP69K devices. Components like hot-melt tanks and guns, however, will never be fully washdown-rated. We label those parts clearly and instruct sanitation teams to bag them before cleaning, eliminating guesswork on the night shift.

Tailored to Your Line

No two plants sanitize the same way, which is why ADCO customizes each washdown machine to your specific chemistry, pressure, and process cadence. Whether you need IP69K electronics, passivated welds, or stainless mesh guarding, we’ll build it so you can focus on uptime, not corrosion control.

Have a sanitation challenge? Contact the ADCO team, we’re built for it.

Contributing Authors:

Clare Blodgett – Clareity Marketing

Colin Warnes – ADCO Manufacturing

Published:

August 25, 2025